How Blockchain Will Radically Improve the Supply Chain

Recent technological advancements and rapid manufacturing growth are having a considerable impact on the global supply chain. For example, artificial intelligence is taking over quality control, Internet of Things (IoT) devices and drones are monitoring manufacturing and maintenance, and more than 1.9 million robots are already deployed in manufacturing and warehousing globally.1

Historically, innovation has often disrupted supply chains in various, significant ways. For instance, the introduction of the PC in the 1980s led to dramatic shifts in supply chain management. Organizations increasingly adopted PCs for word processing, daily operations, and accounting, while map-based interfaces and flexible spreadsheets allowed for more efficient logistics and supply chain planning.2

Today, companies need to be agile, flexible, and responsive to survive. Those that drive continuous innovation throughout their businesses and supply chains – and differentiate themselves in a highly competitive market by remaining dynamic and relevant – are the ones that succeed.

As the pace of change accelerates, improving the efficiency and transparency of your organization’s supply chain becomes critical. Fortunately, blockchain technology can help simplify the process.

Blockchain: The missing link in effective supply chain management

Major companies like Maersk and IBM, who partnered to create the TradeLens platform, are already developing systems to harness the end-to-end visibility and transparency that blockchain technology provides.3

The technology could also help other firms save billions and reduce inefficiencies by integrating with and complementing electronic data interchange (EDI) systems. This represents another evolutionary step in the supply chain, which follows replacing paper-based systems with the digital transfer of documents between trading partners.4

How does blockchain work?

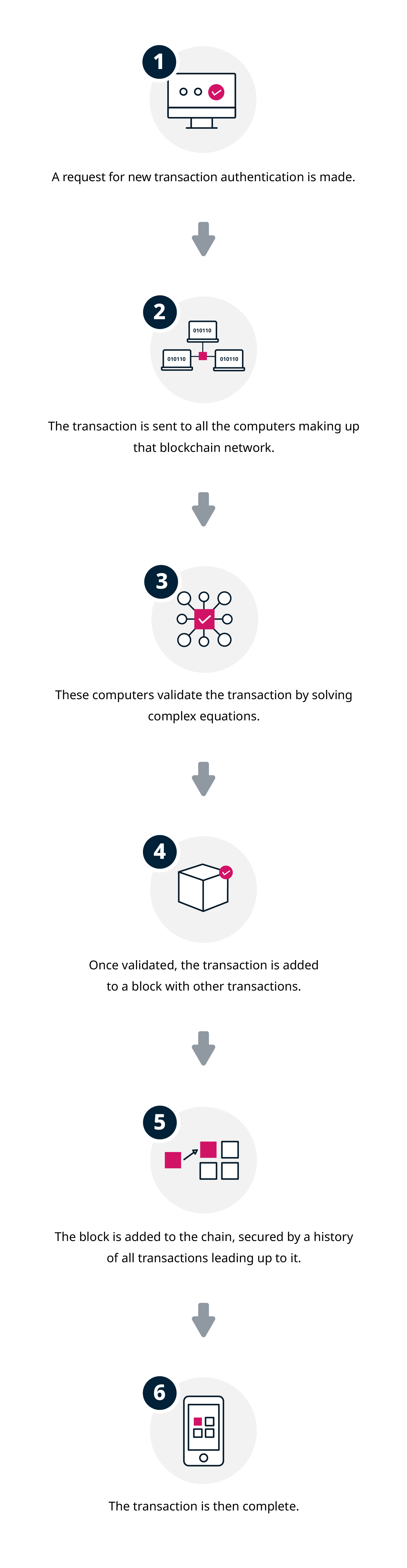

Blockchain is a form of distributed ledger technology that holds records of digital data or ‘exchanges’ in a way that makes them tamper-resistant. When a transaction is requested on the system, it’s broadcast to a peer-to-peer network comprising several interconnected computers called nodes. Each of these solves equations to check and validate the transaction for consistency across the network. Once validated, the transaction is grouped with other transactions to create a block of data for the ledger.5

Businesses can use blockchain technology to track any transaction, making it possible to share documents, personal information, and cryptocurrencies. Because the ledger is fully distributed across the network, it’s very difficult to corrupt. To make a change in the ledger, you’d have to log the change on every node across the entire network simultaneously. If this isn’t done, the network recognizes that one record doesn’t match the rest and flags the transaction as corrupt.6

Think of the technology as resembling a Google document, where many people can view and edit the same document simultaneously, instead of a Word document that’s locked and owned by one person. Every node on the network can access and make changes to the system simultaneously, with ‘Track Changes’ always on.

What is the supply chain?

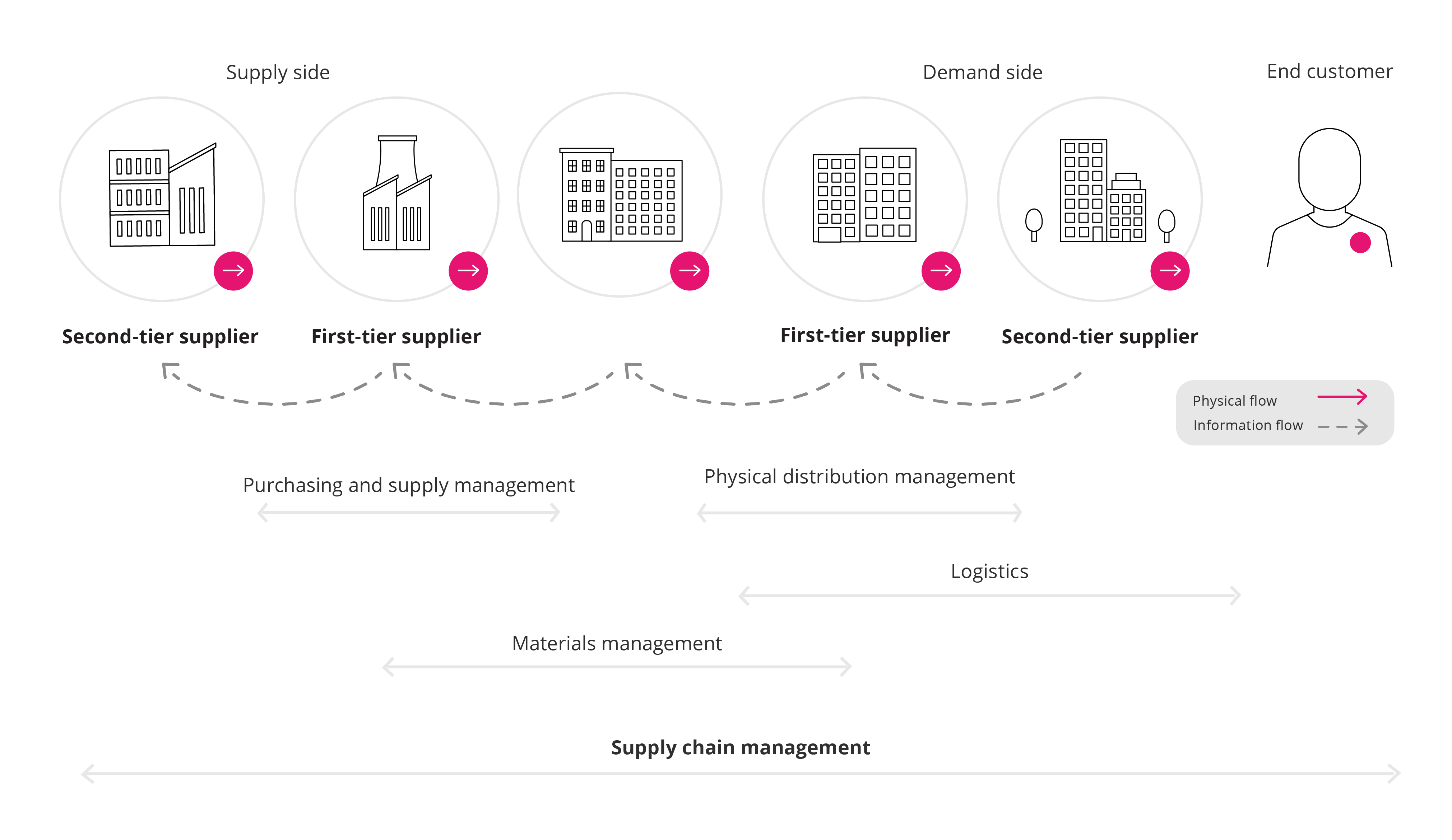

Practically every product that reaches an end-user represents the cumulative effort of many organizations and stakeholders. These are referred to collectively as the supply chain.

Organizations within a supply chain are linked through physical and information flows:

- Physical flows involve the transformation, movement, and storage of goods and materials

- Information flows involve the coordination between partners to control the day-to-day flow of goods and materials up and down the supply chain; it also involves long-term planning7

The management of the product development, sourcing, procurement, production, and logistics of raw materials, products, and finished goods from one point to another is called supply chain management (SCM). Effective supply chain management can lower costs, speed up production cycles, and mitigate risk.8

Supply chain challenges

Lack of supply chain transparency is one of the greatest challenges that organizations currently face.

A survey of 779 business leaders found that 60 percent believed this posed a risk to their businesses.9

There are two dimensions to supply chain transparency, says Alexis Bateman, director of MIT Sustainable Supply Chains at the MIT Center for Transportation and Logistics:

- Visibility: Accurately identifying and collecting data from all links in the supply chain

- Disclosure: Communicating this information, internally and externally, at the appropriate level of detail

To determine the right level of supply chain transparency, organizations should consider their industries, the relevant regulations, their code of ethics, suppliers, customers, and historical supply chain issues, and their acceptable level of risk.10

Inefficiencies in systems – for example, where vendors and suppliers try in vain to connect the dots on who needs what, when, and how – are another common challenge. A few more examples of inefficiencies are bad upstream inventory management, poor allocation of products to stores, fluctuating demand, and even slow shelf rotation. In addition, product recalls are expensive and inconvenient, with companies needing to trace products and suppliers back to their origin to address issues.11

How does blockchain provide supply chain solutions?

Blockchain technology allows companies to track all types of transactions more securely and transparently. The potential impact on the supply chain function is immense.

Using blockchain, companies can trace the history of a product right from its point of origin to where it currently sits.12 Every time a product changes hands, the transaction is documented securely, creating a permanent history, from manufacture to sale.

With the help of this powerful technology, parties collaborating on one shared platform could dramatically reduce the time delays, added costs, and human error frequently associated with transactions. The reduction of intermediaries in the supply chain also reduces the risks of fraud. Finally, where fraud occurs, comprehensive records enable organizations to pinpoint its source.13

A shared blockchain ledger provides a trusted and tamperproof audit trail of the flow of information, inventory, and finance within a supply chain. Using a shared blockchain, companies can synchronize logistics data, track shipments, and automate payments. Moreover, they can do so without significantly altering their legacy systems while sharing only the most relevant data.14

Blockchain and supply chain: The perfect union of efficiency and transparency

The fundamentals of reliability and integrity in supply chains – efficiency and transparency – are provided by blockchain technology.

Efficiency

Blockchain makes global supply chains more efficient by allowing companies to complete transactions directly and without third parties. It also facilitates increased integration of financial and logistics services, enabling greater data collaboration between stakeholders.15

Integrated payment solutions reduce the time between ordering and payment processing, ensuring the proper, timely movement of products. In addition, blockchain and smart contracts help companies enhance compliance, reduce legal fees and fines for late payment of taxes, and curb counterfeiting and fraud.16

Organizations can integrate blockchain with radio-frequency identification (RFID) tags, which use electromagnetic fields to identify and track items. These are frequently used to store product-related information and verify when ownership or possession is transferred, increasing supply chain automation.17 A smart contract is fulfilled when a shipment tagged with RFID codes, which are automatically scanned, reaches its destination.

Transparency

As records on the blockchain can’t be erased, it makes for a transparent supply chain. Also, each step in the supply chain is logged securely, which means that logistics issues can be easily tracked to their source. The same goes for sourcing components or raw materials, which can be traced back to their origin, increasing accountability and transparency, and mitigating illegal activity.18

One study estimates that blockchain’s ability to help prove product provenance could boost global GDP by $962 billion.19 Providing more information about a product’s manufacturer, origin, transfer, and use can establish trust and confidence in the supply chain.

Blockchain in supply chain use cases

The use cases listed below all demonstrate the great impact blockchain technology already has in global supply chains:

- Project Proton, a blockchain pilot implemented by PepsiCo, automated elements of the company’s programmatic ads supply chain through smart contracts. The project used these contracts to reconcile ad impressions from numerous data sources, facilitating payments through digital tokens in real-time and resulting in a 28 percent increase in efficiency20

- Australian car manufacturer Tomcar uses Bitcoin to pay some of its suppliers and accepts the cryptocurrency for payments from three clients in Israel and Taiwan. This process eliminates the need for international payment fees21

- In the food industry, having solid records to trace products to their sources is becoming non-negotiable. For example, Walmart uses IBM’s blockchain-based Food Trust to keep track of their products along every step of the chain. Nestlé, Tyson Foods, Carrefour, and Raw Seafoods, among others, also use Food Trust for this purpose22

- Mining giant BHP is digitalizing its operations through blockchain, using the technology to verify its suppliers and ensuring environmental, social, and governance requirements are met along the supply chain. Last year, the company completed its first blockchain iron ore trade, worth around $14 million, with China Baowu Steel. The trade was facilitated via the MineHub platform23

- South African paper company Sappi and Indian fabric producer Birla Cellulose partnered to create GreenTrack, which tracks fabric products from sustainable forests through to production. The platform has been adopted by more than 250 supply chain partners, including Walmart and Marks & Spencer24

- Walmart Canada used the DL Freight supply chain invoice and payment platform to automate transactions and data points for more than 500,000 annual shipments, tracking these through GPS and IoT-enabled devices. This resulted in shipping discrepancies being reduced by 97 percent25

- Diamond giant De Beers uses blockchain technology to track stones from where they’re mined, right up to when they’re sold to customers. The technology ensures the company avoids ‘conflict’ or ‘blood’ diamonds and reassures their customers that they buy the real deal26

Upskill today and stay relevant in a changing industry

Interested to learn more about blockchain and how it’s used to improve supply chains? One of the best ways to expand your knowledge and stay abreast of the latest applications is to continue your learning journey. Why not update your skills with the Blockchain Technologies: Business Innovation and Application online short course from the MIT Sloan School of Management? Over six weeks, you’ll examine how blockchain is transforming the foundations of our economic and social systems, and learn how to drive greater efficiencies in your company. Click here for more on what to expect.

The Institute for Management Development (IMD), in turn, offers the Leading Digital Innovation in Supply Chain and Logistics online program. This five-week program from the globally recognized business school can help you identify opportunities to streamline and optimize your organization’s supply chain.

Expand your knowledge of blockchain with an online course

- 1 (Jan, 2020). ‘Rapid technology advancements in manufacturing’. Retrieved from Industry Today.

- 2 Herold, D., et al. (Mar, 2021). ‘The emergence and adoption of digitalization in the logistics and supply chain industry: An institutional perspective’. Retrieved from Emerald.

- 3 (Jul, 2021). ‘How blockchain technology is beefing up supply chain visibility’. Retrieved from Maersk.

- 4 Grewal, J. (Apr, 2020). ‘Blockchain and EDI: Do they complement or compete with each other?’. Retrieved from IBM.

- 5 Conway, L. (Nov, 2021). ‘Blockchain explained’. Retrieved from Investopedia.

- 6 Conway, L. (Nov, 2021). ‘Blockchain explained’. Retrieved from Investopedia.

- 7 (Nd). ‘What is supply chain management?’. Retrieved from Council of Supply Chain Management Professionals. Accessed November 11, 2021.

- 8 Grimshaw, J. (May, 2020). ‘What is supply chain? A definitive guide’. Retrieved from Supply Chain Digital.

- 9 Forde, M. (Feb, 2020). ‘60% of procurement leaders say lack of transparency is a risk, survey finds’. Retrieved from Supply Chain Dive.

- 10 Harbert, T. (Feb, 2020). ‘Supply chain transparency, explained’. Retrieved from MIT Sloan School of Management.

- 11 Gaur, V. & Gaiha, A. (May, 2020). ‘Building a transparent supply chain’. Retrieved from Harvard Business Review.

- 12 Jones, H. (Apr, 2021). ‘How the need for secure supply chains is propelling blockchain’. Retrieved from strategy+business.

- 13 Jones, H. (Apr, 2021). ‘How the need for secure supply chains is propelling blockchain’. Retrieved from strategy+business.

- 14 Gaur, V. & Gaiha, A. (May, 2020). ‘Building a transparent supply chain’. Retrieved from Harvard Business Review.

- 15 Rejeb, A., et al. (Oct, 2021). ‘Blockchain technologies in logistics and supply chain management: A bibliometric review’. Retrieved from MDPI.

- 16 Gohil, D. & Thakker, S. (Apr, 2021). ‘Blockchain-Integrated Technologies for Solving Supply Chain Challenges’. Retrieved from Emerald.

- 17 Rejeb, A., et al. (Oct, 2021). ‘Blockchain technologies in logistics and supply chain management: A bibliometric review’. Retrieved from MDPI.

- 18 Ma, R. (Jan, 2020). ‘How blockchain tech is solving problems in the supply chain sector’. Retrieved from Forbes.

- 19 (Oct, 2020). ‘Time for Trust: The Trillion-Dollar Reasons To Rethink Blockchain’. Retrieved from PWC.

- 20 Ma, R. (Jan, 2020). ‘How blockchain tech is solving problems in the supply chain sector’. Retrieved from Forbes.

- 21 Pawar, T. (Oct, 2021). ‘Blockchain technology for supply chain management in industry 4.0’. Retrieved from Medium.

- 22 Murphy, M. (Mar, 2020). ‘Who is buying into IBM’s blockchain dreams?’. Retrieved from Protocol.

- 23 Del Castillo, M. (Feb, 2021). ‘Blockchain 50 2021’. Retrieved from Forbes.

- 24 Del Castillo, M. (Feb, 2021). ‘Blockchain 50 2021’. Retrieved from Forbes.

- 25 Shein, E. (Sep, 2020). ‘Walmart Canada IoT-blockchain system nearly eliminates shipping discrepancies’. Retrieved from TechRepublic.

- 26 Smits, M. & Hulstijn, J. (Mar, 2020). ‘Blockchain applications and institutional trust’. Retrieved from Frontiers.